Where the idea of Engineered Stone is born?

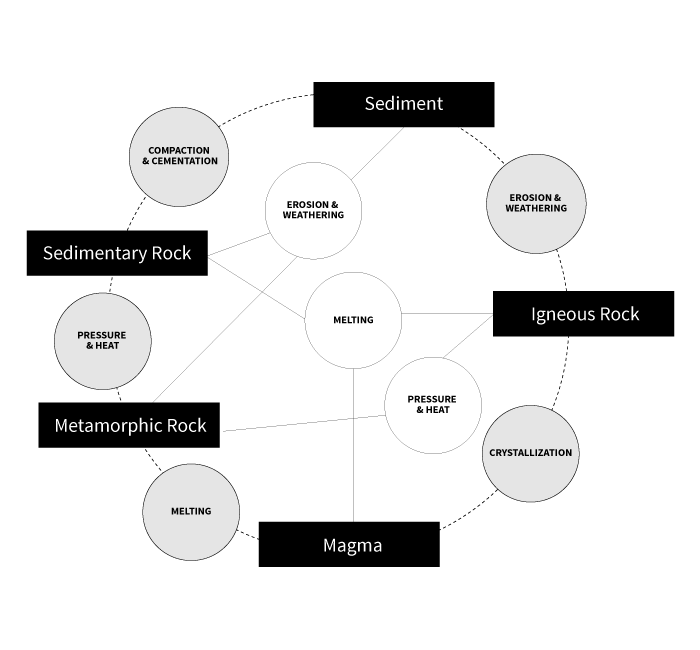

In order to go back to the concept of agglomerate we can make reference to mineralogy and introduce the definition of “clastic” rocks: the word “clastic” means broken and reduced to small fragments; these sedimentary rocks are made up of detritus of various natures and dimensions, from several millimetres to powder.

The processes of moulding and cementing, which have taken place, over an extremely long period of time through the geological ages have created the NATURAL AGGLOMERATES

Conglomerates and Breccias for example, are natural agglomerates made up of fragments of rocks that have cemented together and hardened over time.

In the ENGINEERED STONES the processes of forming and cementing take place in a much shorter time, thanks to the modern moulding technologies and the binding characteristics of new materials, such as the organic polymers.

The formula that identifies an Engineered Stone is based on a simple concept.

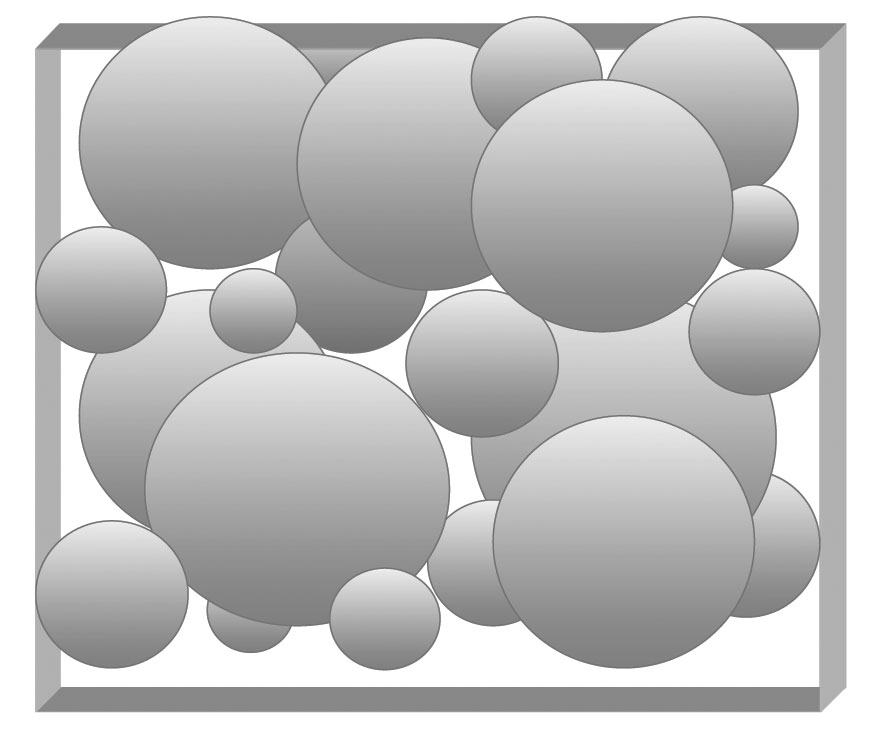

When we consider a certain volume, which may be the shape of a slab or the mould for a block, the granular materials have a certain space to fill:

The remaining space is filled up by powders (fillers) and by organic binders (generally unsaturated polyester resin).

The Engineered Stone are for all intents and purposes COMPOSITE MATERIALS made up of:

granular material: which forms the structure

powder: which fills the interstitial spaces

binding agents: which cements the product

additives and coloring agents: which confer the desired technical and aesthetic traits

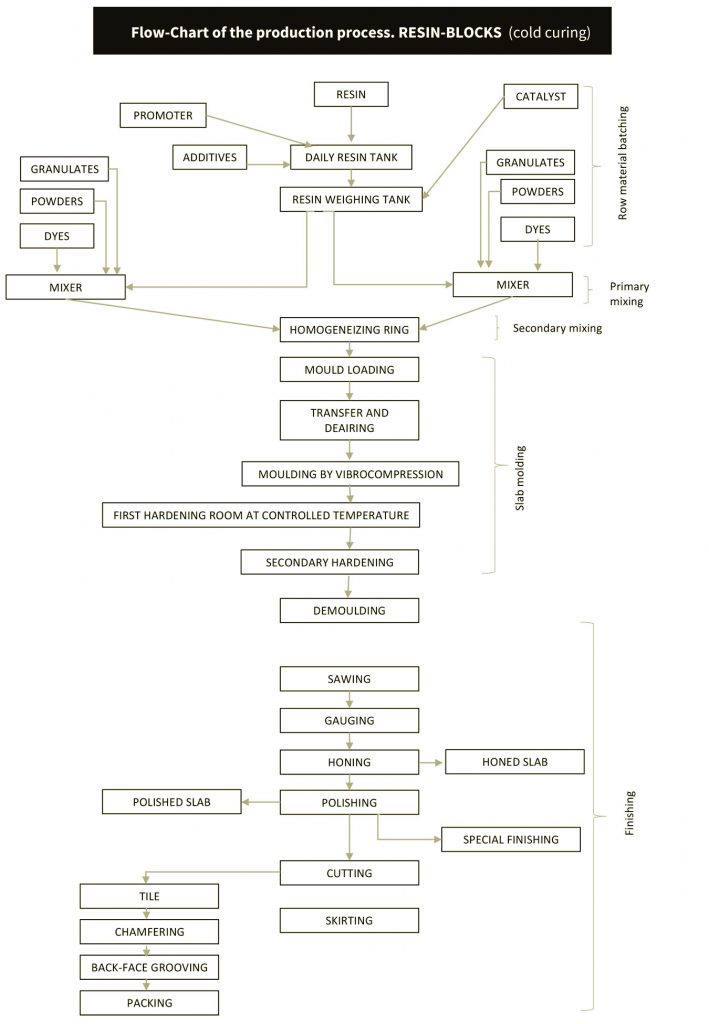

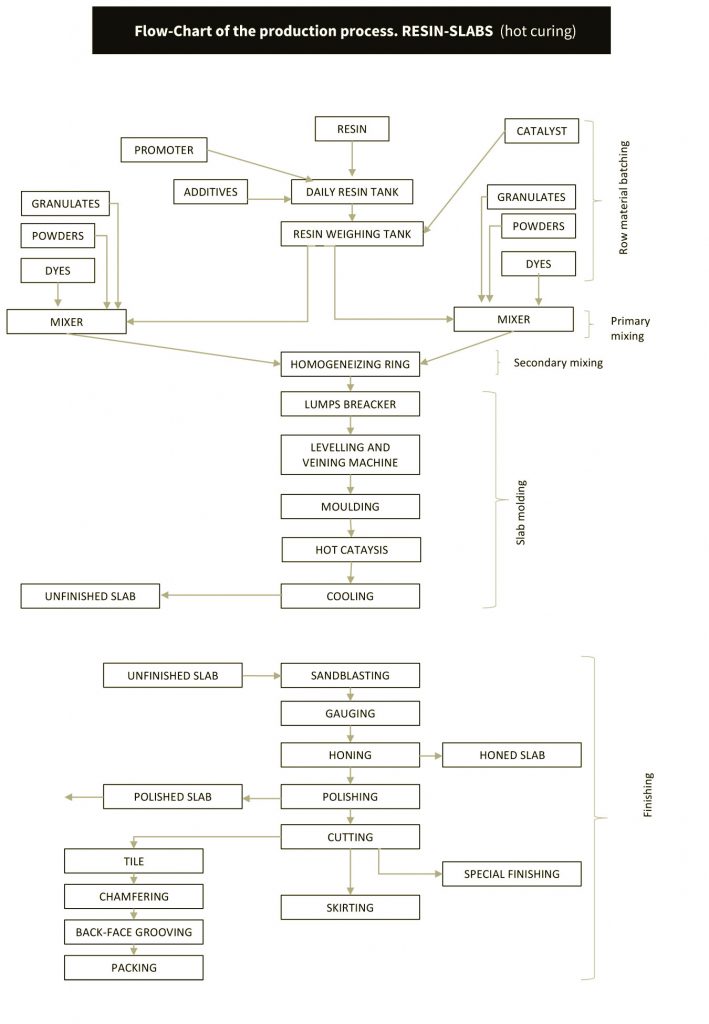

Today Engineered Stone is industrially manufactured by means of different moulding technologies, mainly through vibration or vibration and compression under either atmospheric pressure or vacuum, and the traditional inorganic binder has been replaced by unsaturated polyester resin.

The original raw materials for Engineered Stone are marble, granite, feldspar, or quartz, which can be found in large dimensions in nature and which can be crushed or have already been crushed by natural events.

This industry can also make use of marble and granite excavation refuse, which is an interesting contribution to solving the problem of the environmental impact of the stone processing industry.